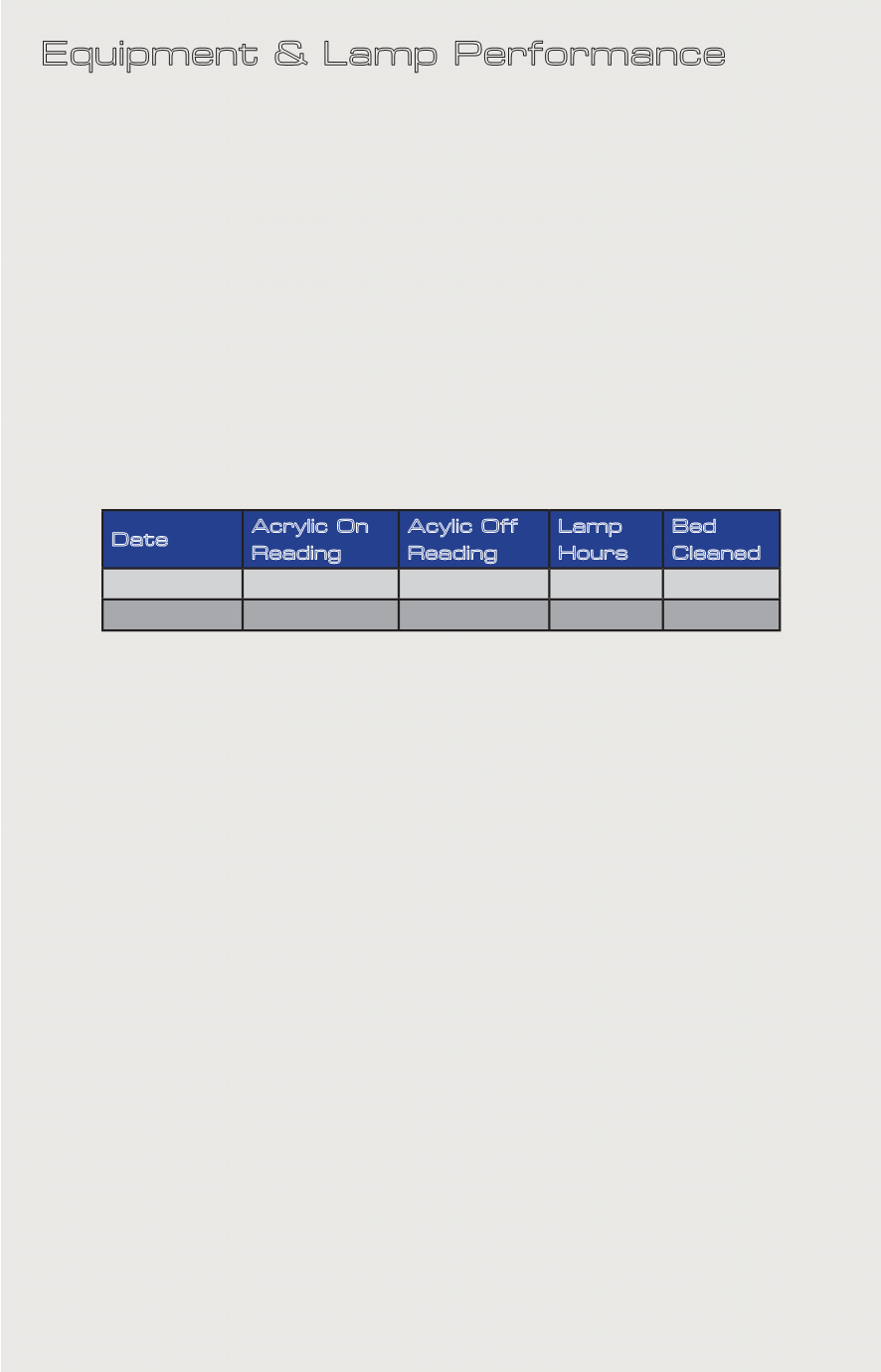

Equipment & Lamp Performance

The most successful salon operators meter their equipment’s

output regularly, and keep a careful log of their meter readings.

Contact your supplier and purchase a handheld UV meter that is

designed to give the most accurate readings for your tanning

system. These simple meters are typically built to read UV intensity

at only one wavelength (normally 365nm). It is important to note that

they give a relative reading only!

Three different meters might give three different readings for the

same lamp in the same bed or booth on the same day. That’s not

important. What is important is that your UV meter will help you

to see how your equipment is functioning. These meters can show

you how your lamps and acrylics will degrade over usage. Establish a

notebook with a page for each booth or bed in your salon. Here is an

example of how your notebook should read:

When you put new VHO lamps into your equipment, you should

operate them for at least 5 hours initially, to distribute the mercury

within the lamps and bring them up to full output. In the case of HO

lamps, no break in time is required. Once the lamps are stabilized,

take and record your initial UV intensity reading. Test them regularly.

You’ll want to change your lamps when the output falls to 70% of

the original meter reading. Thus, if your initial reading was 20, you’d

want to re-lamp when the output falls to 14.

Always test your equipment under the same circumstances. We

suggest a five minute warm-up, and readings taken with the meter

in the center of the equipment, resting on the acrylic, or within a

preset distance from the lamp. If your test procedures vary (e.g.,

incoming voltage), your readings will vary, and the information will be

inaccurate. It’s not just lamps that wear out. As they age, acrylics

degrade, and begin to filter out some of the UV coming from the

lamps. When this happens, even unused lamps will hardly tan your

customers—and it’s time for new acrylics. Meter your equipment’s

output with new acrylics, and watch for a significant output change,

(acrylic on vs. acrylic off) as the acrylics age.

In addition, the existence of written records and test results will save

you time and money if you ever have to diagnose certain equipment

problems. Therefore, you need to meter your equipment and keep

good records. You’ll be glad you did!

Date

Acrylic On

Reading

Acylic Off

Reading

Lamp

Hours

Bed

Cleaned

12/01/14 17

18

5

Yes

01/01/15 16

17

102 No